sales@adityainstruments.co.in - GST NO. : 27AFOPC9275N1ZN

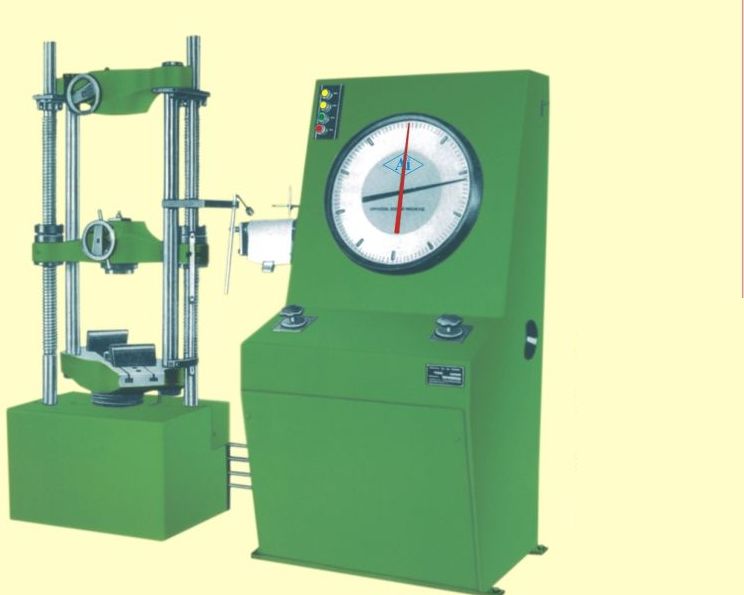

Universal Testing Machine

| Business Type | Manufacturer, Exporter, Supplier |

| Specification | |

| Brand Name | Aditya Instruments |

| Country of Origin | India |

| Automatic Grade | Automatic |

| Color | Green |

| Finish | Paint Coated |

| Maximum Capacity | 100kN |

| Dimensions | 2032x750x1960 mm |

| Weight ( Approx ) | 1500 Kg |

| Display Type | Analog |

| Driven Type | Mechanical |

| Ram Stroke | 150mm |

| Business Type | Manufacturer, Exporter, Supplier |

| Details | |

| Brand | Aditya Instruments |

| Material | Mild Steel |

| Automatic Grade | Automatic |

| Country of Origin | India |

| Capacity | 100 Ton |

| Phase | Three Phase |

| Power | 2.6 kW |

| Frequency | 50Hz |

| Product Code | Electronic Universal |

We hold expertise in offering Electronic Universal Testing Machine in the global market. This Electronic Universal Testing Machine is widely trusted for reliable performance. The Electronic Universal Testing Machine, provided by us, is in great demand at several industries to conduct several tests like test tensile, compression, bending and shear tests on metals & other materials.

Our company Aditya Instruments can introduce itself as a quality-driven leading organization in manufacturing ductile tester and electronic universal testing machines in India. We have earned reliability from numerous reputed industrial organizations in India and are usually specialized in the manufacturing of diverse sophisticated equipment such as an Electronic Universal Testing Machine. Some of the world-class features of our machinery are :

Full fledge membrane keyboard

Data entry for entering specimen dimensions.

Scrolling results in failure.

Quality Push-button zeroing of load, displacement and extension.

Results on the panel include ultimate load, displacement at ult load,

For the world-class testing machinery just remember our name.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Blue & White |

| Automatic Grade | Automatic |

| Application | Testing, Metal Material, Plastic |

| Voltage | 220V |

| Type | Universal Testing Machine |

| Weight | 5-10 Ton |

| Warranty | 1 Year |

| Country of Origin | India |

| Brand Name | Aditya Instruments |

| Power Supply | AC220V 50HZ |

| Tensile Space | 700mm |

We Aditya Instruments, are one of the leading computerized Universal Testing Machine Manufacturers. We owe the operations and devoted support of our team to help us in delivering an exact range of test equipment and machines as per the developing industry requirements. Our certified quality control procedures help us in manufacturing a comprehensive range of universal testing laboratory equipment. We manufacture instruments as per National and International standards and also as per customer necessities. Our testing machinery is recognized for its high durability and extreme quality result. We have a testing facility that tries and tests each functioning aspect of the machinery we manufacture.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Aditya Instruments |

| Features | Accurate Measurement |

| Weight | 3.5 Ton |

| Voltage | 440V |

| Country of Origin | India |

| Warranty | 1 Year |

| Type | Universal Testing Machine |

| Application | Testing |

| Power | 10-15kw |

| Automatic Grade | Automatic |

| Color | Blue & White |

| Display Type | Anlogue Dial Type |

| Maximum Capacity | 100 KN |

We, Aditya Instruments are one of the prominent universal testing machine suppliers. Our testing machine is designed for testing metals and other materials under tension, compression bending, crosswise and shear loads. Hardness tests on metals can also be accompanied. Our testing machine is designed to perform tensile, compression, winding and shear tests on most extensively varying materials, both in form of test pieces and as end products. A hardness test on metals can also be achieved.

Some of the salient features of our machinery are

Loading Accuracy as high as ±1%

Straining rate to cover a wide range of materials

Continuous roll type load elongation recorder

High reading accuracy due to the large size and design of the dial

We, Aditya Instruments are one of the prominent universal testing machine suppliers. Our testing machine is designed for testing metals and other materials under tension, compression bending, crosswise and shear loads. Hardness tests on metals can also be accompanied. Our testing machine is designed to perform tensile, compression, winding and shear tests on most extensively varying materials, both in form of test pieces and as end products. A hardness test on metals can also be achieved. Some of the salient features of our machinery are :

- Loading Accuracy as high as 1%

- Straining rate to cover a wide range of materials

- Continuous roll type load elongation recorder

- High reading accuracy due to the large size and design of the dial

- For world class Universal Testing Machines Exporter, contact us now.

PENDULUM DYNAMOMETER

The oil pressure in the main cylinder actuates the special dynamometer system. Pressurised oil in the loading cylinder pushes up the measuring piston proportionately and deflects the pendulum. The piston is constantly rotated to eliminate friction. The system has effect ive damping arrangement to ensure smooth return of pendulum after sudden breakage of test piece. This unit permits selection of favourable hydraulic ratios producing relatively small frictional forces.

Specifications

| Model | UTM-10 | UTM-20 | UTM-40 | UTM-60 | UTM-100 | UTM-200 | UTM-300 | |

| Maximum Capacity | kN | 100 | 200 | 400 | 500 | 1000 | 2000 | 3000 |

| 1st Measuring Range | kN | 0-100 | 0-200 | 0-400 | 0-600 | 0-1000 | 0-2000 | 0-3000 |

| Minimum Graduations | kN | 0.2 | 0.4 | 1 | 2 | 2 | 4 | 5 |

| 2nd Measuring Range | kN | 0-50 | 0-100 | 0-200 | 0-300 | 0-500 | 0-1000 | 0-1500 |

| Minimum Graduations | kN | 0.1 | 0.2 | 0.2 | 0.5 | 1 | 2 | 2.5 |

| 3rd Measuring Range | kN | 0-25 | 0-50 | 0-100 | 0-120 | 0-250 | 0-500 | 0-600 |

| Minimum Graduations | kN | 0.05 | 0.1 | 0.25 | 0.2 | 0.5 | 1 | 1 |

| 4th Measuring Range | kN | 0-10 | 0.20 | 0.40 | 0-60 | 0-100 | 0-2000 | 0-3000 |

| Minimum Graduations | kN | 0.02 | 0.0 | 0.1 | 0.1 | 0.2 | 0.4 | 0.5 |

| Clearance for tensile at fully descended working piston | mm | 50-700 | 50-700 | 50-700 | 50-800 | 50-800 | 50-900 | 50-900 |

| Clearance for compression test at fully descended working piston | mm | 0-700 | 0-700 | 0-700 | 0-800 | 0-850 | 0-900 | 0-900 |

| Clearance between columns | mm | 500 | 500 | 500 | 600 | 750 | 850 | 850 |

| Ram Stroke | mm | 150 | 200 | 200 | 250 | 250 | 300 | 300 |

| Straining/piston speeds {at no load) mov | movmin | 0-300 | 0-150 | 0-150 | 0-100 | 0-80 | 0-45 | 0-50 |

| CONNECTED LOAD | ||||||||

| HP | 1.3 | 1.3 | 2.3 | 2.5 | 3.5 | 6.5 | 8.5 | |

| V | 400-440 | 400-440 | 400-440 | 400-440 | 400-440 | 400-440 | 400-440 | |

| @ | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| DIMENSIONS L x W x H (approx.) | mm | 2032x750x1960 | 2032x750x1960 | 2060x750x2180 | 2265x75x2534 | 2415x815x2900 | 3000x1200x3600 | |

| STANDARD ACCESSORIES | ||||||||

| Clamping jaws for round specimens diameter | mm |

10-20 20-30 |

10-20 20-30 |

10-25 25-40 |

10-25 25-40 45-55 |

10-25 25-45 45-70 |

20-40 40-60 6080 |

25-50 50-70 70-90 |

| Clampings jaws for flat specimens thickness | mm |

0-10 10-20 50 |

0-10 10-20 50 |

0-15 15-30 65 |

0-15 15-30 70 |

0-22 20-45 45-70 90 |

0-25 25-50 50-75 100 |

0-25 25-50 50-75 100 |

| FOR COMPRESSION TEST | ||||||||

| Pair of compression plates of diameter | mm | 120 | 120 | 120 | 120 | 160 | 220 | 220 |

| FOR TRANSVERSE TES | ||||||||

| Table with adjustable rollers Width of rollers | mm | 160 | 160 | 160 | 160 | 160 | 200 | 200 |

| Diameter of rollers | mm | 30 | 30 | 30 | 50 | 50 | 70 | 70 |

| Maximum clearance between supports | mm | 500 | 500 | 500 | 600 | 800 | 900 | 1000 |

| Radius of punch tops | mm | 6.12 | 6.12 | 12.16 | 16.22 | 16.22 | 30.40 | 50.75 |