sales@adityainstruments.co.in - GST NO. : 27AFOPC9275N1ZN

The Advantages Of Using A Wire Torsion Testing Machine For Your Industry

Posted by Admin on May, 16, 2023

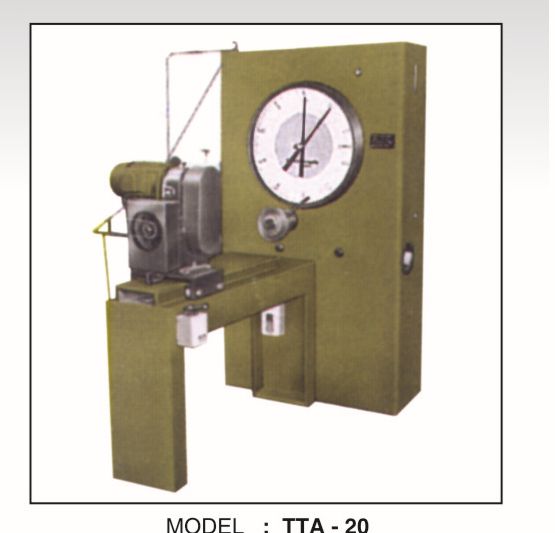

Product quality and dependability are of utmost importance in today's highly competitive industrial landscape. Using a wire torsion testing machine can have significant advantages for industries like manufacturing, aerospace, and automotive that rely on wire-based components.

Following are the advantages of using a wire torsion testing machine in your industry's testing and quality control processes.

Precise Strength Evaluation

A wire torsion testing machine uses controlled twisting forces to precisely measure a wire's strength. The resistance of the wire to deformation, fatigue, and torsional stress can be better understood through this testing procedure. Manufacturers can guarantee the production of wire-based components of high quality and dependability by accurately assessing the strength characteristics of the wire.

Increased Product Reliability

Using a wire torsion testing machine in your quality control procedures increases overall product reliability. By exposing wires to controlled torsional powers, makers can recognize possible shortcomings, imperfections, or irregularities that might make them think twice about the products' presentation. This proactive way to deal with quality control forestalls exorbitant disappointments and guarantees consumer loyalty.

Assurance of Longevity

Throughout their lifespan, components based on wire, such as springs, cables, and connectors, frequently face repeated forces of rotation or twisting. Manufacturers can evaluate the wire's durability by using a wire torsion testing machine to simulate these real-world conditions. This makes it possible to produce sturdy parts that can withstand prolonged use without sacrificing performance or safety.

Effective Material Usage

A wire twist testing machine works with material choice streamlining. Manufacturers can evaluate the performance characteristics of various materials-based wires by testing them under controlled torsional forces. They can choose the material that is best suited to particular applications with this knowledge, balancing costs, flexibility, and strength. Streamlined material choice further develops item proficiency and diminishes squandering.

Streamlined Process of Development

The use of a wire torsion testing machine in the process of development speeds up product design and shortens the time to market. By leading early and iterative twist tests on wire models, makers can recognize likely shortcomings or configuration blemishes speedily. This considers opportune changes and streamlining, keeping away from exorbitant revisions or product reviews in later phases of creation.

Keeping up with Industry Standards

To guarantee the safety and dependability of their products, various industries have specific regulations and standards. A wire twist testing machine helps with meeting these necessities by providing a state-sanctioned testing strategy to wire-based parts. Manufacturers can demonstrate compliance by carrying out torsion tests following industry standards. This increases customer trust and opens doors to new markets.

Improved Process Knowledge

Wire torsion testing machines provide useful information about how wires behave under various torsional loads. Manufacturers can gain insight into wire performance, failure modes, and fatigue life by analyzing this data. Improved product performance and cost-efficiency can be achieved through process enhancements like material selection, wire diameter optimization, or design modifications thanks to this information.

Conclusion

Industries that rely on wire-based components benefit greatly from employing a wire torsion testing machine. This specialized testing equipment enables manufacturers to produce products of high quality that are dependable in a variety of ways, including accurate strength evaluation, enhanced quality control, increased product durability, and shorter time to market.

Industries can stay competitive, meet regulatory requirements, and provide superior wire-based components to their customers by incorporating a wire torsion testing machine into their processes.

Search

Category

Recent Posts

- How Metal Safety Depends on a Vickers Hardness Testing Machine

- Electronic Universal Testing Machine - Product, Benefit & Feature

- What to Expect from a Good Torsion Testing Machine Exporter

- How Rockness Hardwell Testing Machine Ensures Material Quality and Strength?

- Brinell hardness testing machine: An effective means of assessing material hardness

Leave a Comment